HPS provides innovative solutions in today’s complex food market and delivers value added end to end solutions for our customers

Tag Archives: HPS Engineering

Prostan is a cost effective technology for milk processors to apply, removing excess protein from liquid milk in-line.

HPS have completed a project that integrated Bacterial Removal Separators into an evaporation system. This was the first installation of it kind globally

Raw Materials Tracking Project

HPS Engineering have implemented site wide caustic and acid reuse systems that use NF technology to polish the solutions and send them back to multiple users on the site.

HPS develops and implements processes utilising ion exchange to extract valuable components from milk such as Lactoferrin from Milk & Whey sources.

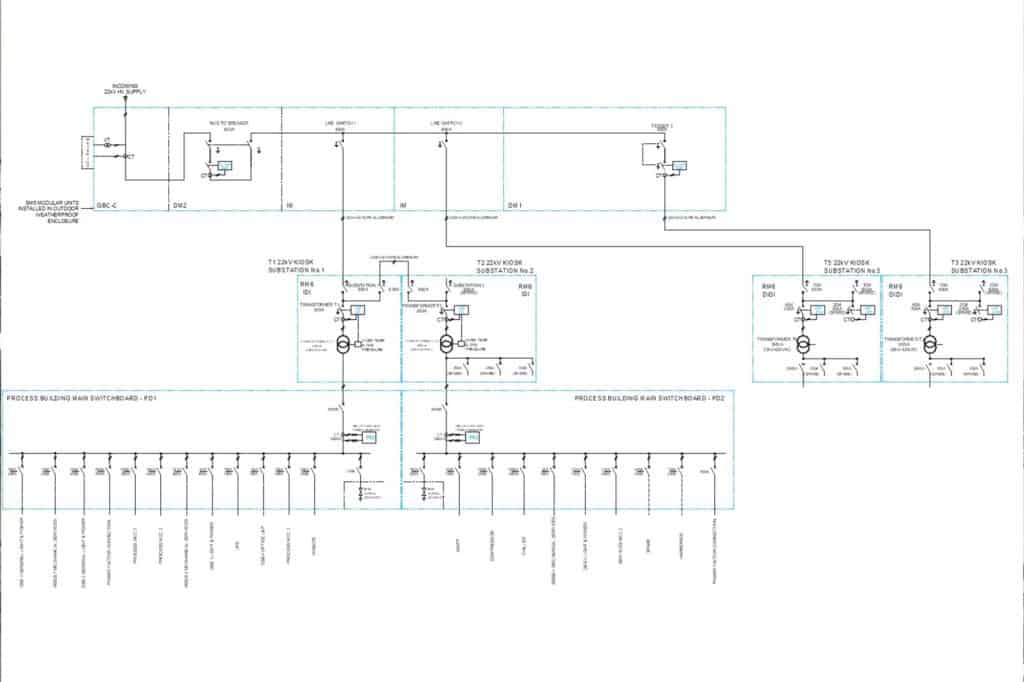

Our electrical engineers design HV, LV, and control systems, including single line diagrams and switchboard design, supporting the project execution team.

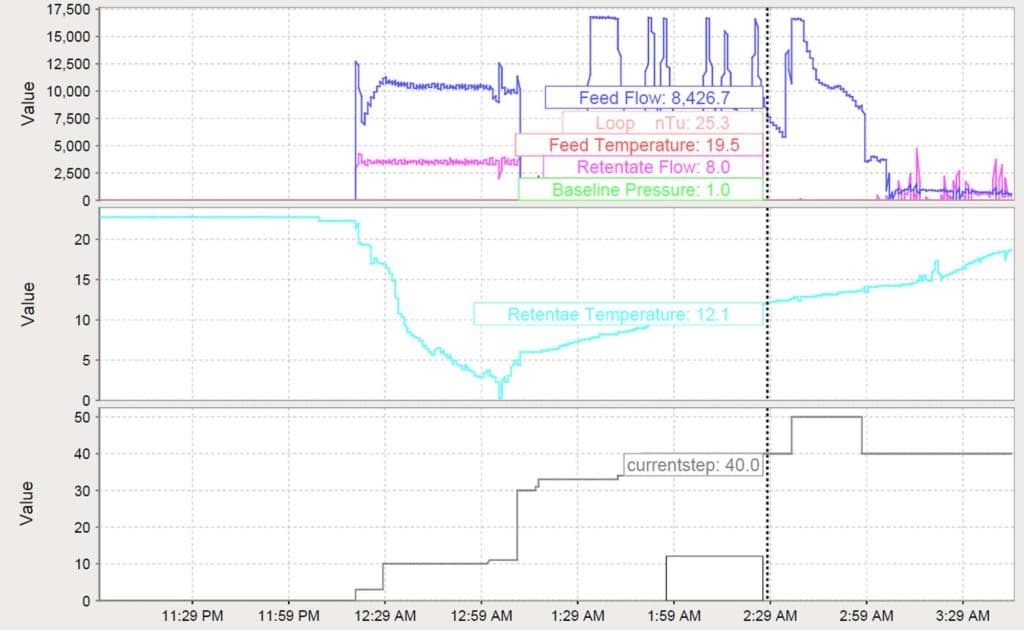

HPS can execute control of the process plant in various DCS or PLC logic and SCADA/HMI systems.

Our Project engineers work on all parts of the design for new and existing manufacturing or processing facilities.

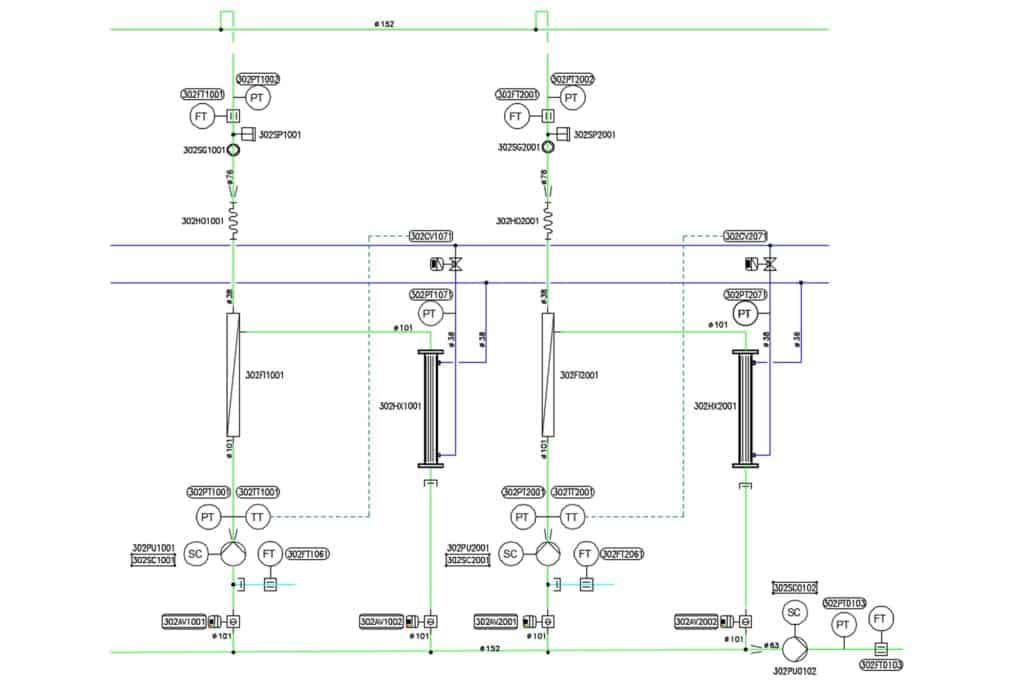

Complete Process & Instrumentation Drawings (PID’s) for all plant design including incorporated equipment specification within the drawing.

Our projects require complete project management – we can work to Prince and Agile methodologies.

HPS Engineering undertakes works in Hazardous areas and ensures the design & installation complies to AS/NZS3000.

HPS Engineering is able to provide a custom and tailored solution to a variety of applications requiring membrane filtration.

Chem-Dose is an integrated and distributed IBC storage system for various chemicals classified as Dangerous Goods.